Factory Direct Price Good Thermal Stability High Strength Magnesia Carbon Firebrick Refractory Carbon Brick for Ladles Converter

Basic Info.

| Model NO. | RS-RC-001 |

| Shape | Brick |

| Material | Magsite |

| Application | Converter, Electric Furnace, Electric |

| Advantage | Good Thermal Stability Supply Ability |

| OEM | Yes |

| Bulk Density/G.Cm3 | ≥2.77 |

| Melting Point ºC | 2800ºC |

| Apparent Porosity/% | ≤6 |

| Package | Carton with Pallet |

| Price Factory | Outlets |

| Material Feature | Anti Corrosion Brick |

| Processing Service | Cutting, Moulding |

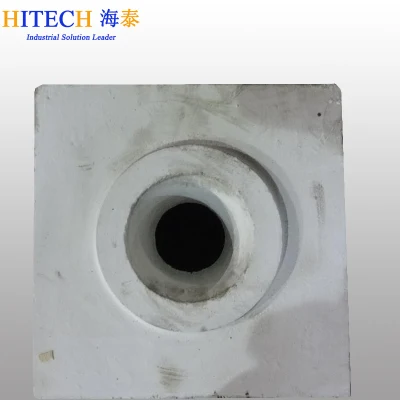

| Usage | Phosphoric Acid Reaction Tank |

| Product Name | Anti Corrosion Carbon Brick |

| Transport Package | International Standard |

| Specification | Customizable |

| Trademark | Zhengzhou Rongsheng Refractory Co., Ltd. |

| Origin | Zhengzhou Rongsheng Refractory Co., Ltd. |

| HS Code | 6902200000 |

| Production Capacity | 500ton/Tons Per Year |

Product Description

Factory Direct Price Good Thermal Stability High Strength Magnesia Carbon Firebrick Refractory Carbon Brick For Ladles Converter

Product Description

Carbon brick is a high temperature resistant neutral refractory product made of carbon as raw material and adding an appropriate amount of binder.The raw materials of carbon bricks include anthracite, coke and graphite, as well as binders such as pitch, tar and anthracene oil. Anthracite has less volatile matter and dense structure. When producing carbon bricks, it is mostly used as aggregate, metallurgical coke (coal char) is added, and asphalt is used as binder.

Specification

Physical and chemical indexes of Anti Corrosion Carbon Brick

| Physical and chemical parameters of carbon bricks | ||

| Index | ||

| Bulk density (g / cm3), ≥ | 1.70 | |

| Open porosity /% , ≤ | 15.0 | |

| Stress strength / MPa, ≥ | 36.0 | |

| Air permeability mPa , ≤ | 1.0 | |

| Oxidation rate /% , ≤ | 8.0 | |

| Average pore size , ≤ | 0.1 | |

| Thermal conductivity, ≥W / (m K) | At room temperature | 16.0 |

| 600ºC | 20.0 | |

| Note: The above index is for reference only, if you need specific indicators, please contact consultant. | ||

Product Application

Anti Corrosion Carbon Brick are mainly used inCarbon Bricks are widely used in the metallurgical industry. Of which carbon bricks are more used in the blast furnace. Many blast furnaces' furnace bottom and hearth are built with carbon bricks. Carbon Bricks uses, Rongsheng Carbon Bricks supplier. Carbon Bricks also can be used for pickling bath, plating bath in the electroplating industry, for the dissolving tank in the paper manufacturing industry, for the reactive tank and storage tank in the chemical industry, and for the autoclave in the petrochemical industry.

Production Process

Packaging & Shipping

Packaging : Packed by sea-worthy wooden pallet + shrink wrapped + carton For example, Standard size of Fireclay brick : 230x114x65mm Shipping : 384pcs/plt x 18plts in one 20 feet container;

Company Profile

RS Refractories Co., Ltd. is located in Henan, China. Our company has professional scientific and technical personnel and production team, and we have our own fully automated factories. For more than ten years, we have focused on the development and innovation of refractory materials and high-temperature furnace technology, and strive to provide customers with comprehensive, personalized and cost-effective services with high-quality products. Our products are widely used in electric power, metallurgy, petrochemical and other fields, and are exported to more than 70 countries and regions in the world such as Europe, America, Oceania, Southeast Asia, and the Middle East.

RS Refractories Co., Ltd. is a first-class supplier of refractory materials, we can provide you with the most advantageous quotations and products. Looking forward to be your partner!

Certifications

FAQ

Q1. Are you Manufacturer?

A: Yes, of course, our factory is in Xinmi,zhengzhou city,Henan province.Q2. Can we visit your company?

A: Sure,welcome at any time,seeing is believing.Q3. Do you accept OEM?

A: Yes, we can do OEM.Q4. What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your condition.Q5. What are the payment terms?

A: Usually T/T,but L/C,Western Union etc are available for us.Q6. How long is delivery time?

A: The delivery time will be determined according to the quantity of the order.Q7. How are your products' quality?

A: The products will be strictly inspected before shipment, so the quality could be guaranteed.Q8. How to solve the quality problems?

A: If the products are not confirmed to customer samples or have quality problems,our company will be responsible to make compensation for it.Q9. What is the service life of your bricks?

A: The service life of different bricks is unlike.It also depends on your using condition and method.Q10.How about your company's certification?

A: ISO9001 and Test Report,also we could apply other necessary certification.